Basic Info

| Model NO. | WF-JF |

| Surface Treatment | Sand Blasting |

| Forging Tolerance | +/-0.5mm |

| Standard | GB |

| Certification | CE, RoHS, ISO 9001:2008 |

| Technics | Forged |

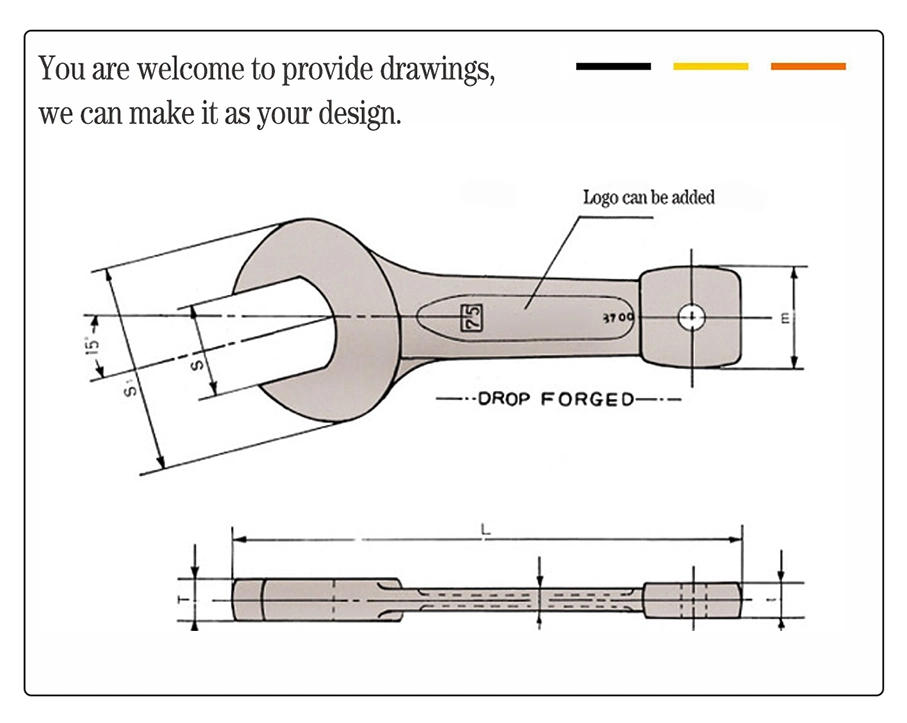

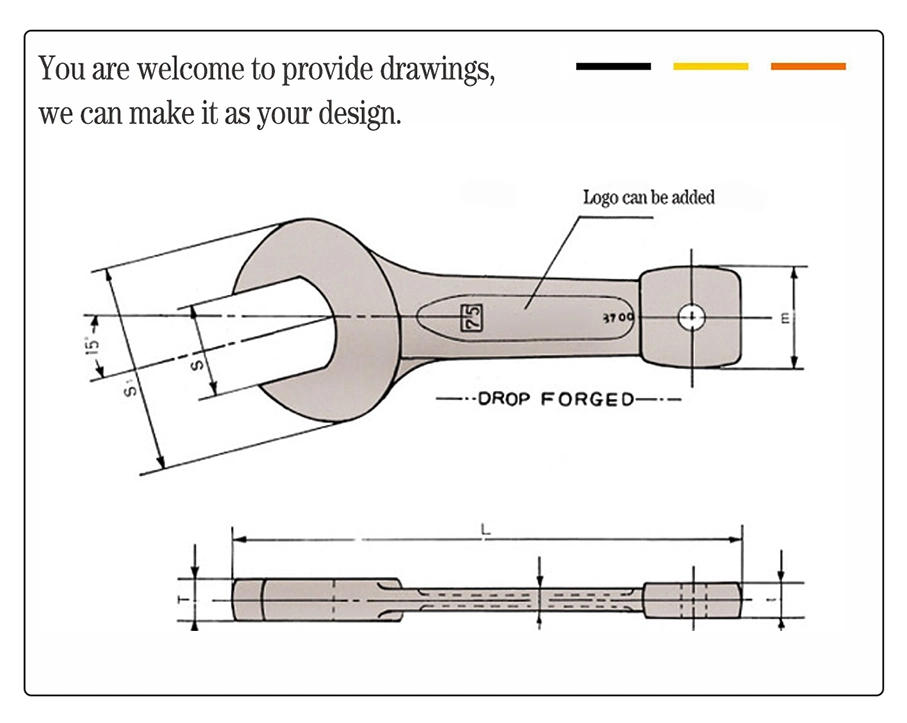

| Supply | Drawing Design |

| Unique | China Gold Supplier |

| Dimensions | Customized |

| Place of Origin | Shandong,China |

| Process | Hot Forging, Heat Treatment |

| Business Type | Factory |

| Quality Certification | ISO9001:2008,AISI,CE,Leo,SGS |

| Machining Service | Your Logo,Charactor,Trade Name,Number |

| Shipping Port | Qingdao |

| OEM Service | Yes |

| Custom Made | Yes |

| Logo Printing | Customized |

| MOQ | 10-1000PCS |

| Free Sample | Yes |

| Transport Package | Plywood Box |

| Specification | SGS, ASTM, ISO9001: 2008, EN124, DIN, GB, CE |

| Trademark | ShengAo |

| Origin | Weifang, Shangdong, China |

| HS Code | 87089910 |

| Production Capacity | 50000PCS/Month |

Product Description

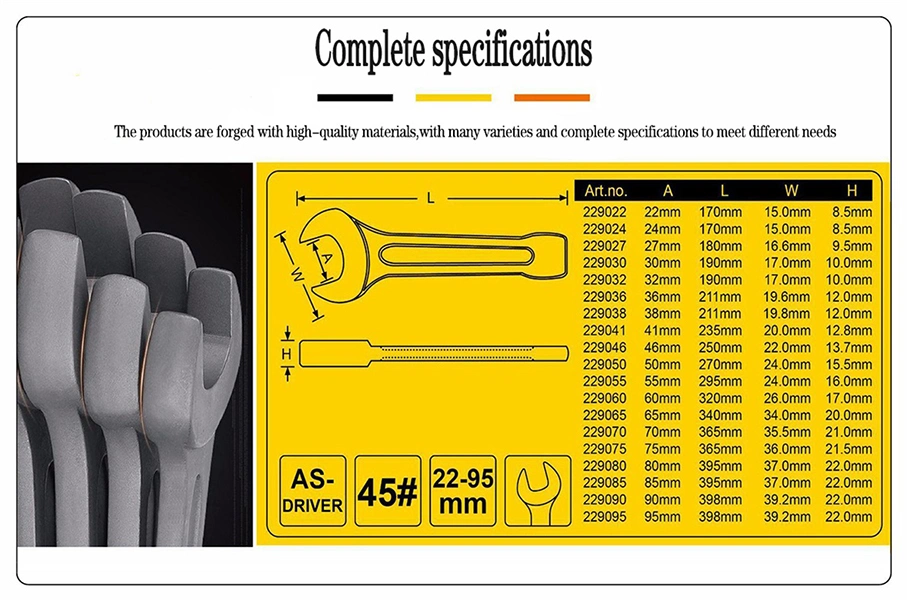

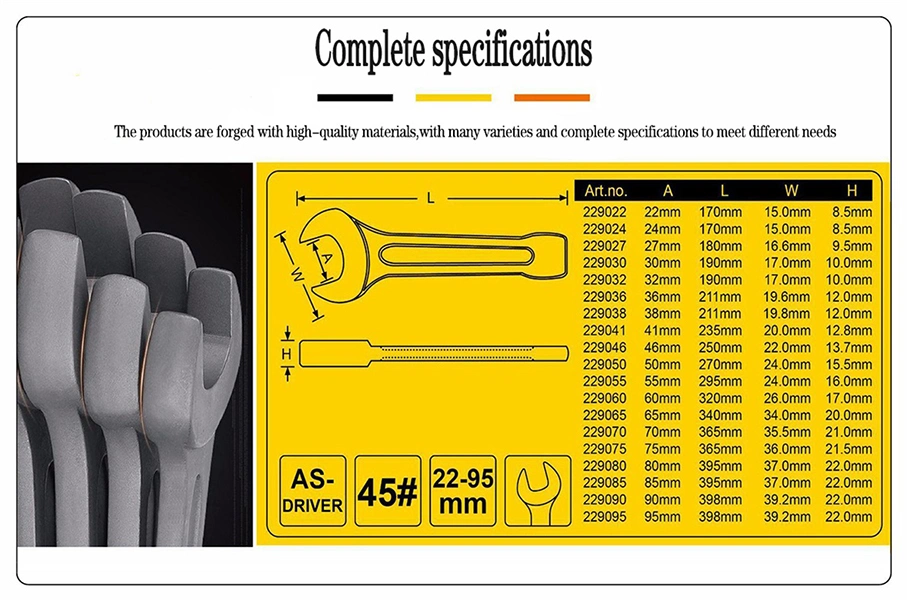

OEM Drop Forged Carbon Steel Double Open End Combination Wrench

Product Discreption Materials: 40CR-V (Chrome Vanadium) Steel; Phosphate treatment,heat-treated;HRC: 48-52 Black sand finished,corrosion resistant; Greater strength and durability; High Quality and Comfortable Use; OEM and Customized: YES We have a mature production process from raw materials to forging, heat treatment, machining, surface treatment, etc. The materials include carbon steel, alloy steel, stainless steel, aluminum and cooper. The main forging press includes 300T, 400T, 630T, 1000T, 1600T and 2500T, which covers product weight from 0.1kg to 100kg. The main machining equipment includes lathe, planer, drilling machine, tapping machine, line cutting, milling machine, CNC machining center, polishing machine etc., ensuring that we can fulfill different machining requirements from our customers. We have an individual team of well experienced QC staff and many high-educated technical engineers who work throughout the whole manufacturing processes i. e., incoming raw materials, production, and final output, to ensure that our products are of high-quality. The main inspection equipment includes chemical analyzer, hardness tester, tensile-strength tester, magnetic powder flaw detector, metallographic analyzer, etc. High quality products, reasonable price, prompt delivery, and superior service ensure marketing competitiveness. Our factory has earned high reputation from customers of home and abroad. We are looking forward to cooperating with you to forge a better future!

| Product Name | forged wrench |

| Material | Stainless Steel: SS201, SS303, SS304, SS316, SS410, SS420Carbon Steel: 4.8, 6.8, 8.8, 10.9, 12.9Titanium: GR1-GR5Aluminum,Brass,etc. |

| Size | 4.8/ 8.8/ 10.9/ 12.9 Ect |

| Standard | ISO,GB, DIN, JIS, ANSI, BSW,ASME |

| Certificate | ISO9001:2008, SGS testing report & RoHS |

| Finishing | Zn- Plated, Ni-plated, Tin-Plated, Radiant Plated, Passivated, Brass plated, Cd- plated, Phosphate Anodize, Cr-plated, Black Oxide etc |

| Heat Treatment | Tempering,Hardening,Spheroidizing,Stress Relieving etc |

| Package | General export package, or according to customer's requirement |

| Delivery time | About 7 -15 days after all details confirmed and able to offering fast delivery for urgent order |

| Customer Service | Replacement at all our cost for rejected products if the part does not match with the PO drawings |

We also can customized manufacture for you according to your requirements. Forging is one of the important methods of metal plastic processing. The main purpose of forging is: forming and modification (improvement of mechanical properties and internal structure). The latter is difficult to achieve by other processes, and forging production also has the advantages of metal saving, high production efficiency, and great flexibility. Forging can make the porosity and pore compaction in the cast structure, crush the coarse cast structure (dendritic grains) into fine grains and form a fibrous structure. When the fiber structure is reasonably distributed along the contour of the part, the mechanical performance of the part can be improved. Therefore,the forged parts have high strength and can withstand greater impact loads. Under the condition of bearing the same impact load, the size of forged parts can be reduced, that is, metal is saved. For example, the United States used a 315MN hydraulic press to forge 272 parts and 3,200 screws of the F-102 F-102, which reduced the weight of the aircraft and replaced the overall beam on the fighter, replacing 45.5-54.5kg. Q: Why choose Shengao product? A: We Shengao have our own plant Weifang Shengao Machinery , therefore, we can surely promise the quality of every product and provide you comparable price. Q: How can I get a quotation? A: Please send us information for a quote: drawing, material, weight, quantity, and request. Q: If we don't have the drawings, can you make drawings for us? A: Yes for sure, please send us the samples. We need about 2-5 days. Q: When can I get my sample/products? A: Tooling need about 20 days, production need roughly 35 days. Q: Do you provide OEM Service? A: Yes, we provide OEM Service, give us drawings and specifications, and we will manufacture accordingly. Q: What is your payment term? A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc. 30-50% TT deposit on order, the balance pay against BL copy. If there's anything I can help, please feel free to contact me.