CNC Diamond Finger Router Profiling Bit and Sink Wheel Holder for Stone Grinding&Milling

Basic Info

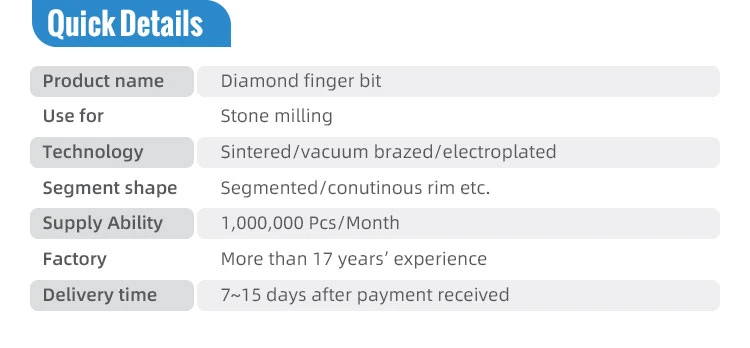

| Model NO. | Diamond finger bit |

| Quality | a+ |

| Usage | Edge Milling |

| Processing Object | Stone |

| Bore | 22.23/25.4 mm or as Required |

| Advantage | High Efficiency, Fast Cutting, Long Life |

| Working Depth | 20/30/40/50 |

| OEM | Accepted |

| Transport Package | Carton |

| Specification | Dia: 20mm or 24mm |

| Trademark | Linsing |

| Origin | China |

| Production Capacity | 20000piece/Month |

Product Description

Diamond Sink Wheel & Finger Bit

Vacuum brazed diamond finger bit adopts advanced production technology, strict product quality inspection process, long service life and stable grinding performanceProduct feature:

1. High efficiency, long life and fast milling speed.2. It is a kind of milling bit suitable for all kinds stone processing.Product specification:

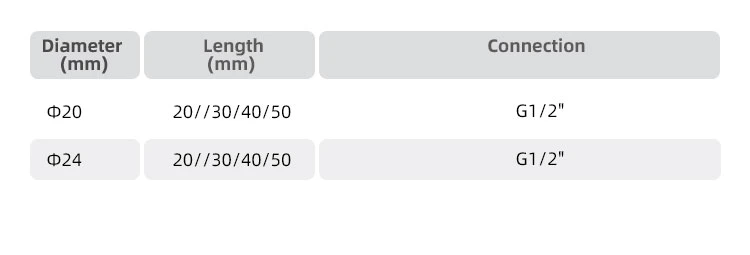

| Diameter(mm) | Length(mm) | Connection |

| 20 | 20//30/40/50 | G1/2" |

| 24 | 20//30/40/50 | G1/2" |

Jiangxi Linxing Diamond Tools was established in 2003 (officially renamed in 2014, formerly known as "Linxing Tool Factory"), and is located in the Industrial Park of Tianfan Street Town, Poyang County, Shangrao City, Jiangxi Province. It is a professional enterprise integrating R&D, design, manufacture and sales of diamond tools, stone machinery and other stone processing accessories. The main products include diamond segment, diamond saw blade, diamond wire saw, stone abrasive, stone profile processing tools and stone machinery, etc. which help stone enterprises solve many problems such as cutting, grinding, milling, cutting and drilling.

Jiangxi Linxing Diamond Tools 's actual land area is more than 20,000 square meters. The first phase was completed in 2015. It has 4 self-built workshops, more than 20 sets 3D automatic mixing equipment, more than 30 sets automatic cold-pressing machines, more than 60 sets vacuum sintering machines, and more than 10 sets automatic/semi-automatic welding machines, others equipment such as automatic segment opening machines, sandblasting machines, mixing equipment, laser marking machines, silk screen marking machines, etc. The second phase had been started in 2019, a new wire saw workshop had been built, and several advanced wire saw production equipment had been introduced, including bead sintering machine, flat vulcanizing machine, injection molding and glue injection machine, wire saw edger, etc.

Our company's own brand "Linsing", Chinese "Lin Xing", takes the meaning of "talents are like forests, just in the ascendant", our core concept is creating the brand and talents revitalize the enterprise. By establishing a reasonable talent training system, we have set up a radical professional talent attraction system, gradually established a high-quality team with knowledge, culture, ideals and aspirations. Linxing has more than 200 employees, more than 180 production and grass-roots management personnel, and more than 20 technical personnel and R&D teams. At present, it has founded a solid foundation for our company rapid development. In addition, Linxing has successively won many honorary titles such as "Excellent Enterprise in Poyang County" and "Top 100 Enterprises in Jiangxi Stone Processing Tool Industry". At the same time, through years of hard work, our products have been sold to more than 70 countries and regions at home and abroad, and have won the recognition and trust of customers.

In the diamond tool industry, products are the core competitiveness. The procurement of high-quality raw materials, the continuous updating of product series, and the insistence on product quality stability are the core driving forces for enterprise development. At present, we maintain strong R&D capabilities to ensure the product's cost performance is constantly in the leading industry in the market. In terms of quality, Linxing adopts a "unique" management system for full product inspection, and product instability is kept at a low fluctuation range. Stable and cost-effective products give us the advantage in market competition.

Today, Jiangxi Linxing Diamond Tools is moving towards internationalization, branding and specialization. By continuously improving the brand image and popularity, constantly reflecting and learning in practice, making up for work loopholes, improving service system, and finally realizing the dream of all Linxing employees: let the world know that there is a kind of blue called "Linsing blue".